PRODUCTS

Details

1 Implementation standard

JB/T 10636-2006 Rated voltage 0.6/1kV (Um=1.2kV) copper core plastic insulated prefabricated branch cable

GB/T 19666-2019 General rules for flame-retardant and fire-resistant wires and cables

2 Use characteristics

2.1 Product voltage rating

The rated voltage of the product Uo/U is 0.6/1kV, the maximum allowable voltage of the system is 1.2kV, and the use frequency is 50Hz.

2.2 Scope of application

This product is used for distribution lines with rated voltage of 0.6/1kV and below for distribution of electric energy, and is suitable for distribution systems of residential buildings, office buildings, hotels, hospitals, shopping malls, etc. It is also suitable for lighting systems of highways, bridges and stadiums.

2.3 Laying conditions: The ambient temperature should not be lower than 0℃ when the cable is laid.

2.4 Operational requirements

2.4.1 The maximum allowable working temperature of PVC insulated cable conductor is 70℃, and the maximum allowable working temperature of XLPE insulated cable conductor is 90℃.

2.4.2 The maximum temperature of the PVC cable conductor does not exceed 160°C and the maximum temperature of the XLPE cable conductor does not exceed 250°C during a short circuit (maximum duration not exceeding 5S).

2.4.3 The performance of flame-retardant and fire-resistant cables meets the requirements of the GB/T 19666-2019 standard.

2.4.4 Cable bending radius: not less than 20 times the outer diameter of the cable for single-core cables and not less than 15 times the outer diameter of the cable for multi-core cables.

2.5 Product functional characteristics

2.5.1 The trunk and branch lines of the cable meet the requirements of the corresponding type specification of single-core power cable.

2.5.2 The trunk cable has no joints and good continuity, which greatly reduces fault points.

2.5.3 The use of factory prefabrication can substantially reduce the intensity of on-site construction and shorten the construction laying time.

2.5.4 Reducing the space occupied by laying and can be laid together with other pipelines.

2.5.5 The branch adopts sealed joints, which is maintenance-free and maintenance-free for a long time.

3 Prefabricated branch cable laying construction

3.1 Laying method

● Put the cable tray on the discharge frame (usually the cable tray is placed downstairs, and the cable is tugged and lifted to the specified height).

● Connect the rope for lifting to the cable through the winder, pay attention to the cable's upward lead path, and arrange a suitable bending guide wheel.

● Start the winder and lift the cable. When the cable net set for lifting reaches the roof, hang the net set on the hook prepared in advance.

● Check whether each branch point corresponds to the actual branching path, and fine-tune it appropriately as required, and check the integrity of the entire branch cable.

● Fix each intermediate part of the branch cable one after another with clamps to ensure that the sheathing and insulation at the fixing place are intact.

● Connect the end of the branch cable to the ammeter or current breaker.

● Check the insulation resistance and line conduction of cables and branches.

● Make the connection of the main cable.

3.2 Precautions when laying

● Confirm that the prefabricated branch cable passes safely through the penetration hole.

● Take precautions to prevent damage to the branch in the through-hole during lifting.

Do not apply tension to the branch cable during lifting.

Use a rope with a strength of 4 times or more of the cable weight for lifting.

When the cable is lifted, it should be fixed by appropriate method immediately to prevent the cable from falling and being damaged.

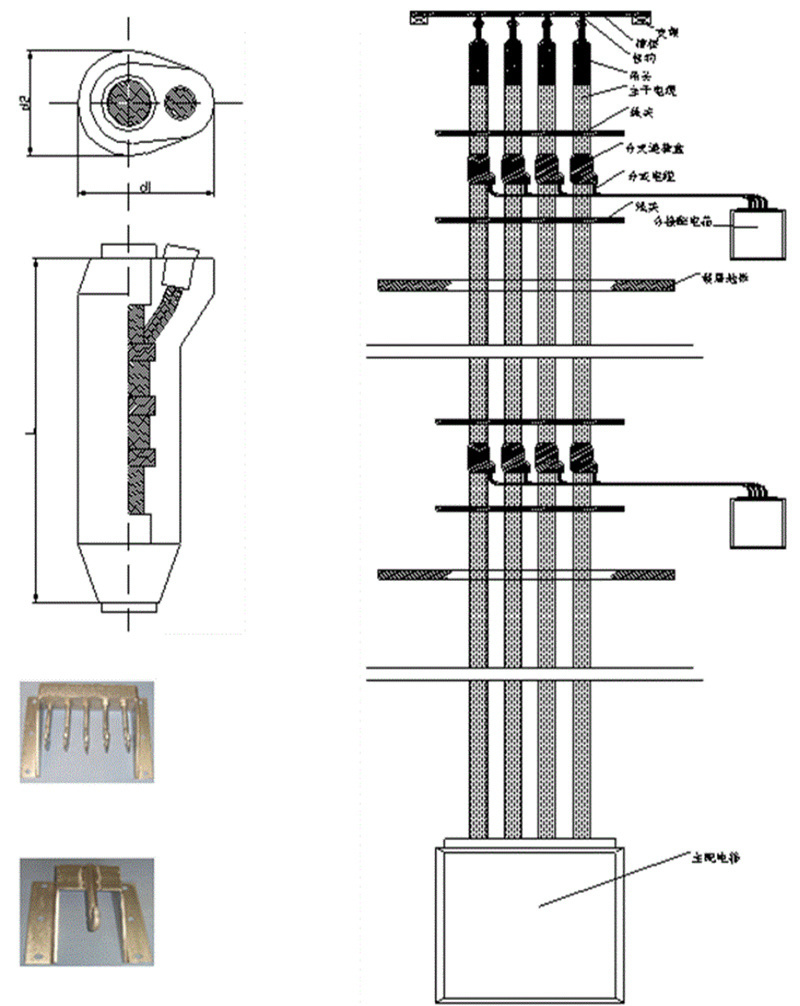

3.3 Branch connector, cross-arms, structure diagram, and installation diagram

Inquiry